Motorcycle Equipment

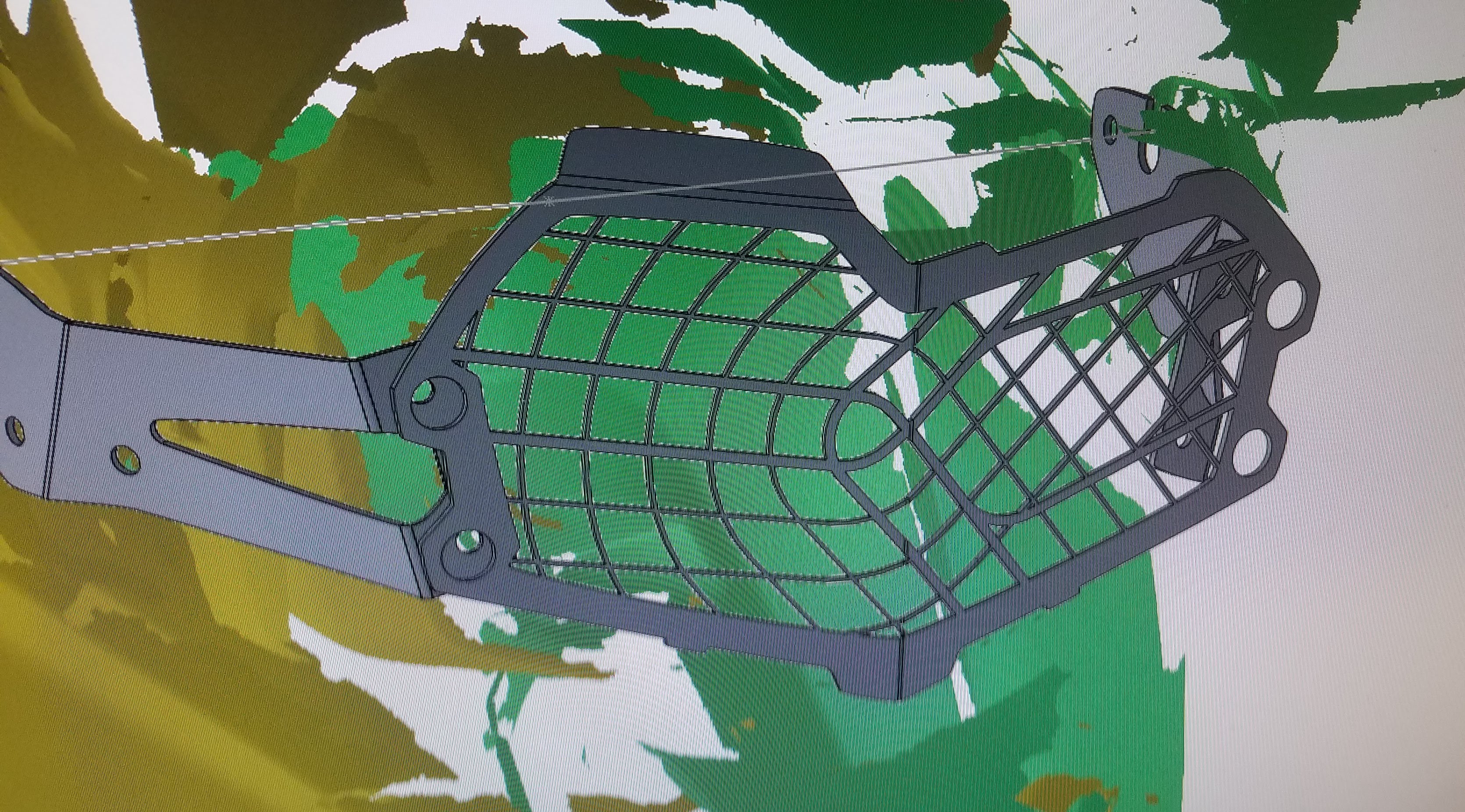

I love to ride my motorcycle. I took this passion to industry when I worked for a small after-market motorcycle gear company in Seattle. The goal of this company is to let riders explore with the freedom and comfort afforded by knowing they and their bike are safe. Pictured above is a headlight guard; keeping your headlight working is a safety and budgetary priority. Let’s walk through the process of going from concept to production on a part like this.

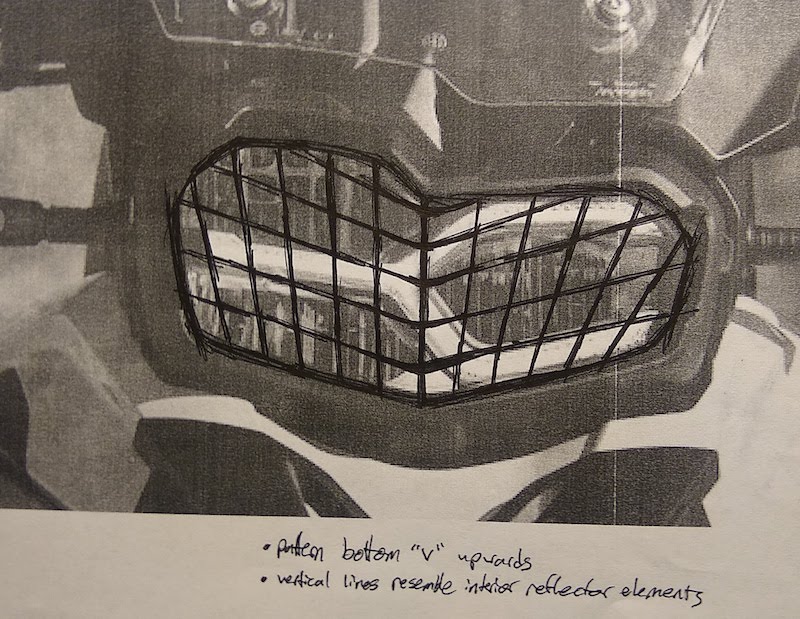

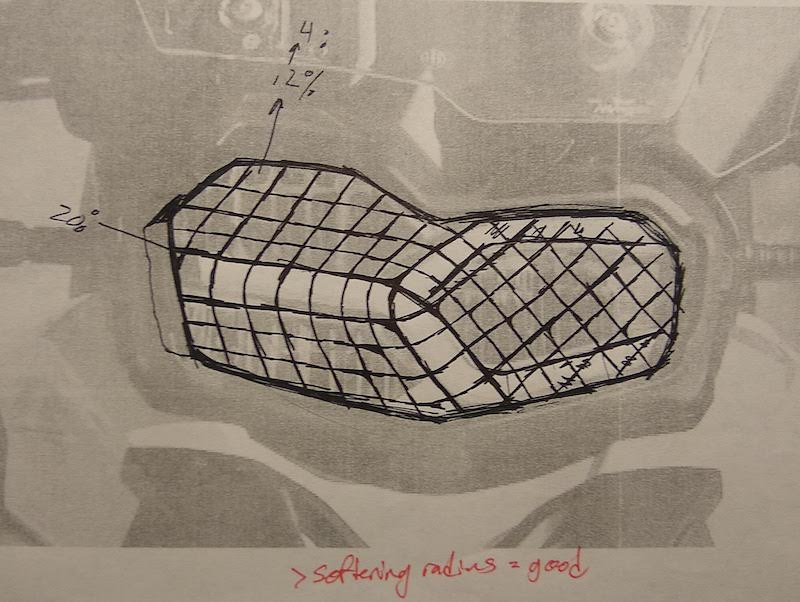

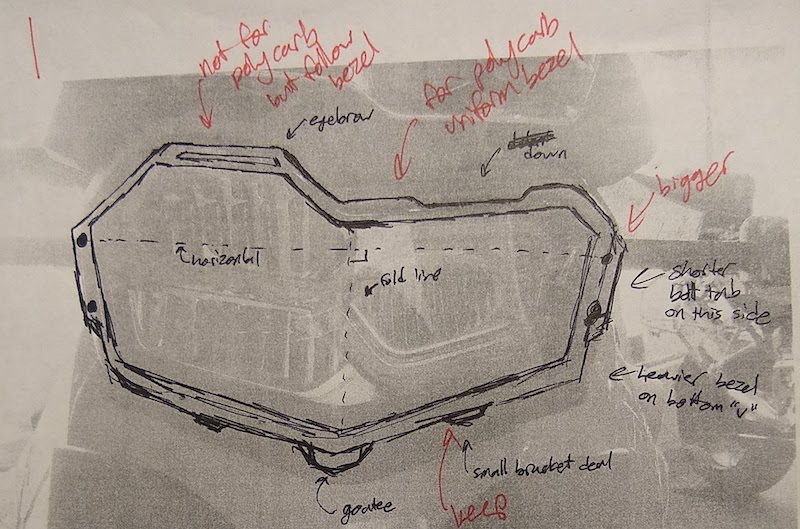

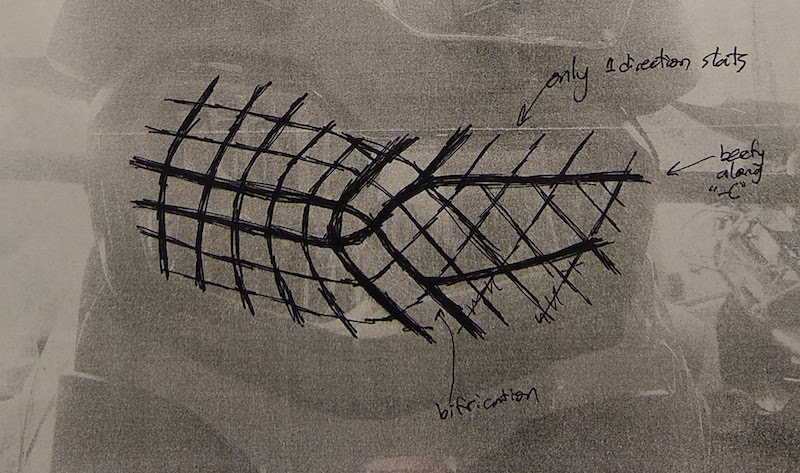

The following are a few of the industrial design sketches I made in the initial ideation phase for this part. It’s critical to balance the aesthetics, strength, and price early on in the design process to reduce the cycles needed to get a part to market.

From initial sketching, we proceed to digitizing the existing geometry of the chosen motorcycle. This is accomplished with the help of a coordinate measuring machine (CMM). The multicolor blobs represent the surfaces of the bike that we scanned. From here, various levels of fidelity prototypes are test-fitted to a variety of motorcycles to ensure consistent fit and easy of installation. In addition, for some parts destructive strength testing is required to verify structural integrity.

Throughout this process, I am in contact with our contract manufacturer to determine which of the “rules” of sheet metal fabrication must be observed and which can be pushed in order to get unusual geometry when needed.

If you are in the market for some motorcycle protection, or you just want to see my parts yourself, please check out the shop!