Agtech Robotics

What does the future of food look like? I got the chance to work with a startup who thinks they have a piece of the puzzle: rethinking vertical farming. Because of the intellectual property involved with this project, you’re going to notice a distinct vagueness to this project. If you have questions, shoot me an email and let’s talk!

What I’m cleared to talk about are the pieces of this system that I worked on with deliberate obfuscation of complete context. Here’s the gist of what I was working on:

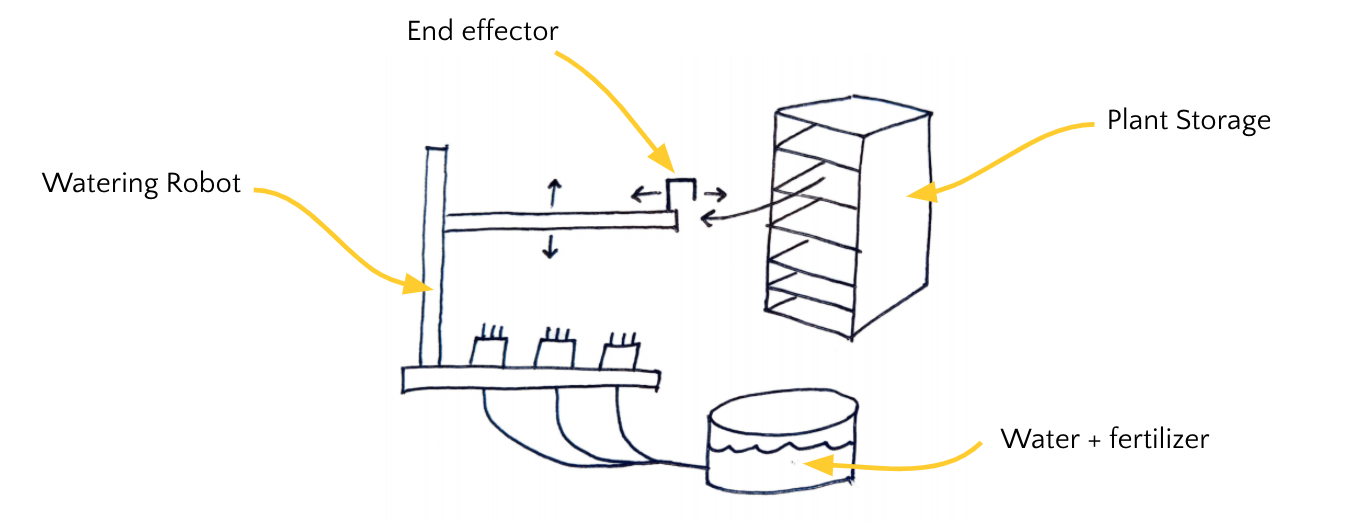

Handling plants is a delicate matter. I was in charge of the interface between robot and plant. Let’s start by talking about the way the watering robot can retrieve a tray of plants so that they can be watered/fertilized.

That tray was designed by yours truly with specific attention given towards those sliding interfaces. In fact, I came in on a few weekends to teach myself how to program the robot that grabs those trays (implementing the python SDK). That way, I could bring a tray in and out a hundred times and determine where it was likely to fail first. My leadership on this front made me the goto for running future routines on the tray retrieval robot.

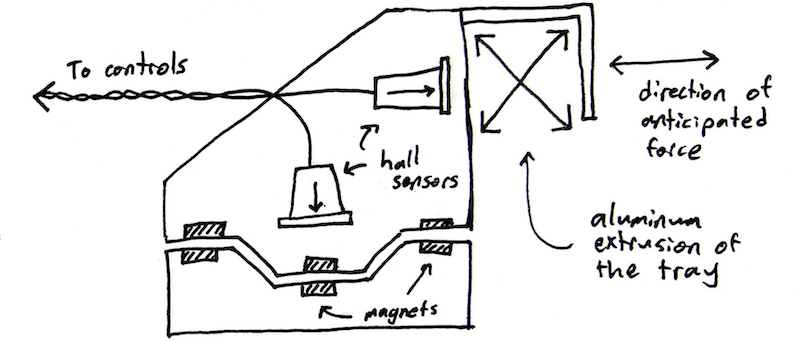

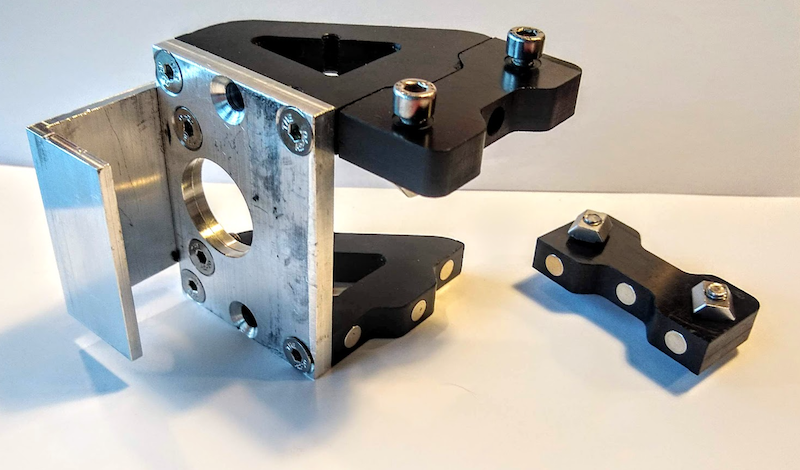

Anyone who has worked with robots at this size can tell you about exciting failure modes, and I’m going to follow that pattern. When a failed homing routine resulted in the robot losing conception of its location, it snagged an unexpected tray and bent the aluminum extrusion like a paper clip before tripping over-current protection and grinding to a halt. To prevent this from happening again, I designed a custom break-away end effector:

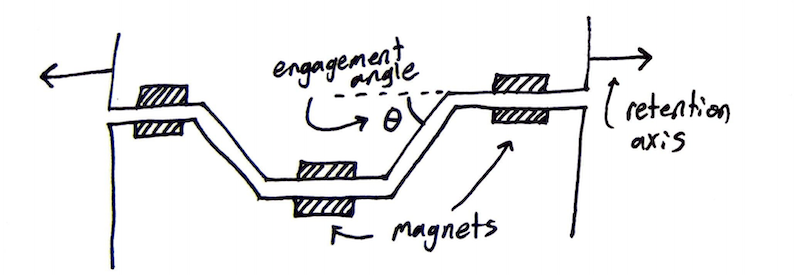

The pull-away resistance of this end effector was carefully dialed in by adjusting the angle of engagement with the complimentary retention geometry.

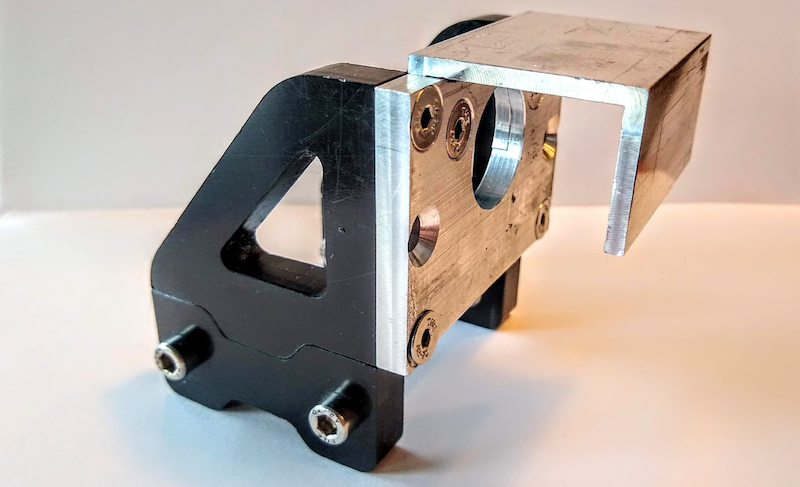

Parts designed in SOLIDWORKS, CAM generated in HSMWorks, and machining performed by me on the CNC mill (Tormach).

In addition to tray/robot interface design, I also worked to ensure that the robot could consistently administer appropriate water/fertilizer. Here you can see a testing apparatus that I designed with an Arduino, relay shield, and a pneumatic cylinder. The test was to determine the optimal needle characteristics to prevent clogging.

Here you see Chase and I navigating downtown Seattle with backpacks full of components destined for an external testing facility. We looked weird on the lightrail.